How to Find a Manufacturer + Save 65% on Product Development

Steve Jobs is – without doubt – one of the greatest founders and entrepreneurs of the past century. Heck, probably ever. His strategic influence and design-first culture helped build Apple into the world’s most valuable company.

That, and some of the most stunning, minimally-designed, intuitive and user-friendly products ever made.

An entrepreneur is no more successful than the quality of what he sells to the world, be it a physical product, service, or idea. We wouldn’t know the late and infamous Apple CEO’s name if the company’s first hastily assembled “factory line” in the Jobs’ family garage hadn’t — against all odds — produced 50 flawless machines.

Tangible products have to be made somewhere, and as the first step in your supply chain, your success lives or dies on the way your products are manufactured.

If your customers receive products that are inconsistently made, or not up to your lofty standards, your brand and business won’t survive a day.

With such a strong tie to your success, it’s always crazy to see entrepreneurs overlook their supply chains. Between wholesalers who take a substantial cut and trading companies that masquerade as factories, there are far too many potholes for online sellers to step in.

And that’s how this guide came to be. We wanted to give online retailers a go-to resource that tells you how to consistently manufacture high-quality products abroad, improve your margins and grow your business.

Specifically, we’ll teach you:

The types of “manufacturers” that exist

How to effectively search for a factory and supplier

How to communicate efficiently with a factory

But first, why.

How (and why) I learned to love manufacturing

The main reason most scalable ecommerce stores look to produce overseas stems from product margins. Though producing outside America creates logistical hurdles and language barriers, when you’re often making a 90% gross margin at scale, those complications are well worth it.

Speaking economically, the reason manufacturing abroad makes sense stems from the value of our currency and cost of labor.

One Chinese Yuan and One Indian Rupee are worth $0.15 and $0.16 USD, respectively. The value of a currency often reflects the cost of living, and when someone can live on a lower salary, they are going to be paid less.

In China, most factory workers are getting paid an average of $2 USD an hour compared to over $23 USD in America. To understand the cost of living, I often compare the price of bottled water in each country: .25 cents in China and over a dollar in America.

Do the Math

To use the water bottle comparison, an hourly worker in China spends about 12% for their hourly pay on a bottle of water. The US worker spend about 4%. You can even that out by working with factories that pay $6 USD an hour to match pay rates based on cost of living.

For most products like shoes or hats, labor is your main cost and the cost of labor in countries throughout Asia is always going to be cheaper than in western countries.

I’ll begin with my experience in China and how I learned the ins and outs of manufacturing.

I started learning Mandarin during my freshman year of high school in 2008. As any bilingual person knows, if you really want to learn a language, you need to go to a country that speaks it.

By 2010, I was a full blown foreign exchange student in Beijing, living with a host family that didn’t speak English while attending a local Chinese high school. During that year abroad, I studied Mandarin 4 hours a day and became fascinated by the manufacturing capability of the country.

Me with some classmates in 2010.

I realized in that year that China was the epicenter of worldwide manufacturing, and I started to build as many factory relationships as I could. When it came time to start my own ecommerce businesses in 2013, I thought the manufacturing process would be easy.

I soon faced the question that stumps entrepreneurs every day: how do you bring a new product to life?

The process was ridiculous, as I faced language barriers, defective products, fraudulent Chinese manufacturers, and more. By the end of it all, I still didn’t really know who I was working with.

After bringing dozens of new products to life over the last 4 years, I’ve realized manufacturing is a huge problem that needs to be solved for ecommerce entrepreneurs. I also realized that I had gained an insane amount of information about exactly how to solve that problem.

So, enough about me. I’m here to share that knowledge with you. Let’s dive into the different types of manufacturers you may be encountering.

Types of Manufacturers

When dealing with overseas manufacturers, you’re probably going to be sorting through a plethora of middlemen. These middlemen are most commonly divided into:

trading companies

wholesalers

sourcing agents (who often work for one of the above)

Actual manufacturers are the factories who produce the products. These can be harder to come by — whether you’re a consumer-facing or B2B seller — as they may not have a strong foundation for dealing with westerners.

With that said, at Sourcify, we only deal directly with factories as the above middlemen make money by taking a cut on top of the actual cost from the factory.

In other words, these middlemen are cutting right into your margins.

Before you can know how to search for an actual factory, you need to know what sets each type of manufacturer apart.

Trading Companies

Trading companies make money by adding a margin to the cost of the actual product costs, and usually deal with a wider array of product categories.

Though trading companies can have great relationships with factories, most professional purchasers will want to go directly to the factories themselves.

If you have a low minimum order quantity though, it may make sense to work with a trading company.

An easy to spot trading company

Trading companies usually have lower order quantity requirements and you could be a big fish in a small sea, rather than a small client of a large factory.

Some trading companies will pretend to be the actual manufacturer with their own factory, so it can be hard to figure out which one you’re dealing with.

Trading companies have distinct implications when you’re sourcing from them:

You may not know who is actually manufacturing your product.

You may not be able to hold the trading company liable in the case of defective products.

Trading companies have a much higher chance of ‘disappearing’ or evading communication.

These scenarios aren’t common – nor unheard of.

Wholesalers

Wholesalers buy a product in bulk and then add their margin to the total cost, making money in a very similar way to a trader.

Businesses who deal with wholesalers often do so because they may have some western representation with warehousing in America. This means your lead time and shipping costs could be reduced.

With that said, when we work with clients who have been buying through a wholesaler, we’ve saved them an average of 65%.

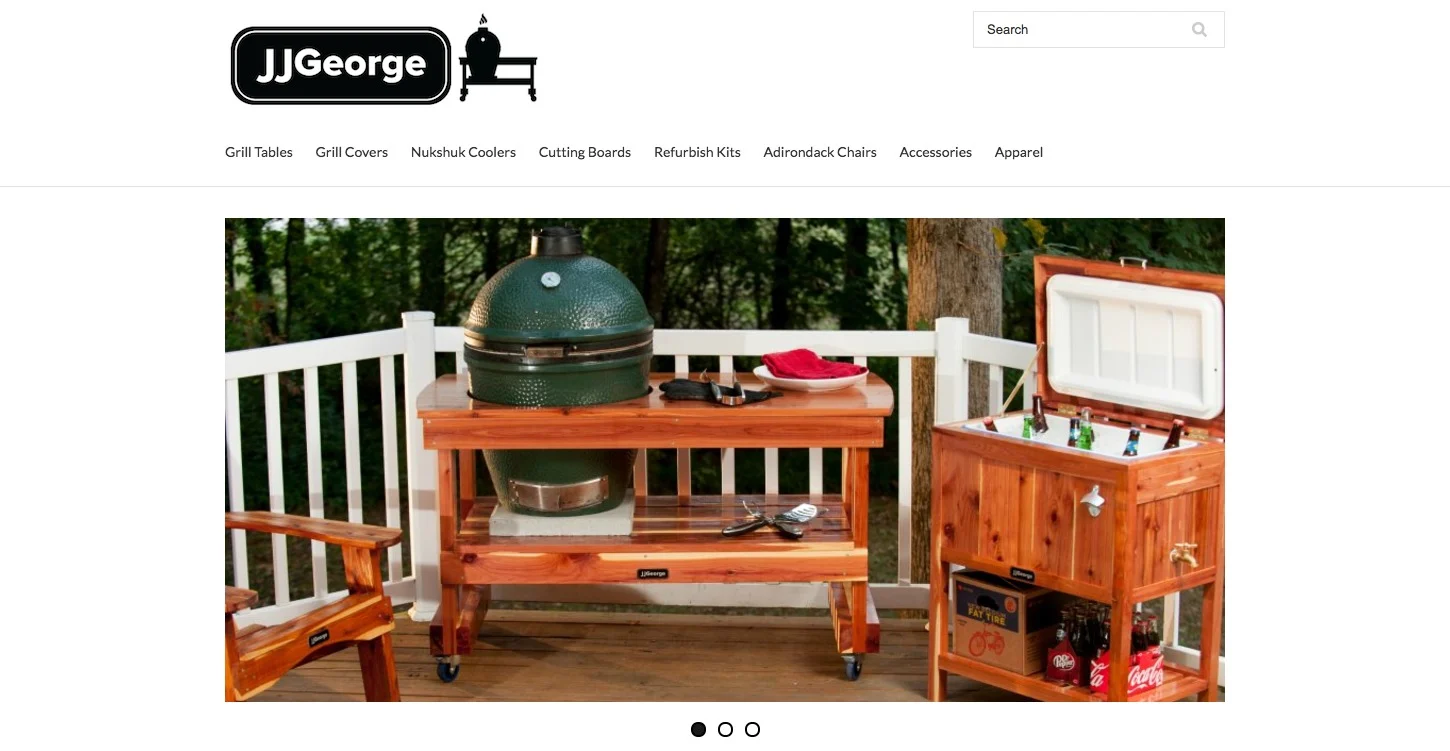

For example, JJ George, a company producing premium grills and grilling equipment, was buying a key component from a American wholesaler. They came to Sourcify knowing they were overpaying for this part and wanted to save costs by going directly to the factory.

Within a week, we found and introduced them to the manufacturer in China who was producing the part for their wholesaler anyway, saving them 45% of their original cost for this part.

If you’re starting a new ecommerce business or expanding to new products, I would recommend avoiding wholesalers because you need that additional product margin to grow.

Also, keep in mind that most wholesalers deal with standardized products and so they don’t have the ability to do much customization – which sets you apart from your competition and is seen as a value add to your brand in the long run, earning you revenue from marketplaces through unique SKUs rather than third-party items.

Factories

When trying to manufacture a product, factories should be your target.

This is your best bet and you’ll have the most profit margin when working with a factory.

The hardest part is finding a good factory with a reliable English-speaking sales rep.

The companies on Alibaba will mostly be trading companies, as they’re in the business of selling the products they acquire from manufacturers and often employ English speaking sales reps to handle the inflow of leads from that website.

There is one legal step you can take to see if you’re dealing with a factory or trading company. Though this doesn’t always work, it is worth being made aware of:

Ask for a copy of the manufacturer’s business license. A Chinese business license will tell you what type of company they have registered as. On the business license, you’ll need to look at the ‘Business Scope’ label. It looks like this, and reads – Jīngyíng Fànwéi:

Determine if it’s legit. If so, they should be more than willing to send you their license. It should look like this:

Scope: See the business scope part of their license which will be a list of categories that the business is legally permitted to operate in. If you think they’ve sent a fake license or if you don’t want to ask the company for their license, you need to find the company’s registration record. These were made available online in 2006 by the AIC (Industrial and Commercial Administration Bureau) for each province of China.

Find the registered province: you need to know which Chinese province the business is registered in to find the company’s registration on the AIC website. Each province has its own AIC website. As an example, here are the links to Beijing, Shanghai, and Guangzhou.

Search for their record using the company’s registered Chinese name. This public record can be used to confirm the information shown on the business license or to check a company’s category (trading company or factory) without them knowing.

The flaw in this process for most ecommerce entrepreneurs is that provinces don’t have English websites, so the search must be done in Chinese. With that said, you can use Google Translate’s Chrome Extension to try and put the pieces together.

Now that you know the types of “manufacturers” and how to confirm them, we’re going to dive into ways to effectively find them!

Finding the right factory to manufacture your products

Most people will start their search using an open database like Alibaba or Global Sources. This is a fine first step, yet you can never confirm a factory from one source. That is why I always recommend you take a cross referencing approach — whether you’re looking for a drop shipper, clothing manufacturer, or anything else.

The Basics of Cross Referencing

If you’ve found a factory you think you’re ready to work with, it’s time to validate their legitimacy before you start working with them. This process will enable you to make sure they are legit without actually visiting them.

You will need to find:

Their complete online presence

See what trade shows they attend

Confirm any business licenses or certificates that they have.

Cross referencing enables you to have multiple sources. You should never rely on one source. Here’s what you’re looking for:

See if your potential factory has their own website and if their email is @[their website]. Though some legitimate factories don’t have websites, the majority will at least have some form of online presence.

See their presence open databases such as Alibaba and Global Sources. On Alibaba, see if they are a Gold Supplier and see what profile information has been confirmed by a third party.

Ask them if they’ve attended trade shows or are a part of any trade organizations. To confirm their attendance, either look them up in the trade show’s directory, or ask for images of their booth at that trade show. At every manufacturing trade show I’ve attended, manufacturers are always eager to take photos of people in their booth to use as validation later.

On Google, conduct a search with their name and the word “fraud.” Checking and double checking their credibility is the most important part of connecting with a potential factory.

The above process will enable you to confirm their reputation and trustworthiness. It is possible to have a good relationship with a manufacturer without meeting them face to face.

Photo Confirmation

The photo confirmation “trick” is the last step you can take to really check if your manufacturer is legit. Most manufacturers have images of facilities online, but how do you know if it’s actually a picture of their facilities?

Ask them to write your name on a piece of paper and take photos of their facilities with that piece of paper in it. Now you will be able to see current conditions of the manufacturer’s facilities while confirming that the facilities they were showing you are theirs (or at least the ones they work at).

This verification step should only be used when you’re about ready to place a order, as it is a nuisance to the manufacturer.

Factory Communication

Once you’ve found a factory that you’re comfortable working with, it’s time to move forward toward a finished production run. The hardest part of this process can be effectively communicating with your factory, as you’ll be facing language barriers and time differences.

A strong factory relationship stems from clear communication.

Relationships are vital to doing business in China, and communication will be essential to your manufacturing success. China literally has a term, “Guang Xi,” that translates to the relationship of people in business.

When speaking with your manufacturer, you will probably be talking to one of their sales reps. Depending on the size of the manufacturer, their office is usually manned by workers with an elementary English level who are sitting in cubicle-like desks.

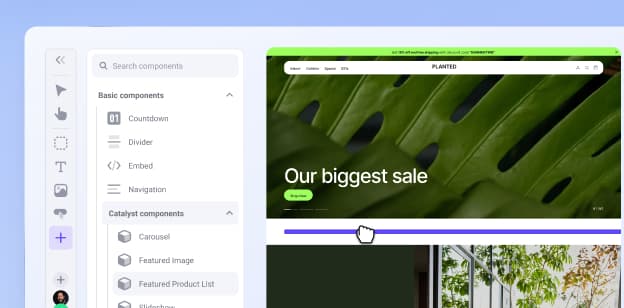

A manufacturer’s office

Though most factories you find online nowadays do have English speaking sales reps, communication can still be variable, and you are going to need to hone in on the ways you want to speak with your factory.

You should never have just one mode of communication, and email isn’t enough because there can be troubles with a factory’s email in China. That is why when we communicate and place customer orders with factories at Sourcify, we always have at least 3 ways of speaking with them. The additional messaging tools we use are:

Skype

WeChat

Whatsapp

Most of your are probably familiar with Skype and Whatsapp. WeChat is a very popular Chinese messaging platform that is a medium between Whatsapp and Facebook. Since Facebook is blocked in China, most people use WeChat in a similar way by sharing moments on a timeline.

In my 7 years in and out of China, it is very rare to meet someone who doesn’t have WeChat.

When speaking with a manufacturer or supplier, they will rarely get on the phone because their English level may not be good enough to speak and their ability to type English is much better. That is why written communication is usually the go to method.

For that reason, when communicating with them, you need to make your sentences as simple as you can. Do not use complex words. Sales reps may be using Google Translate or a comparable tool, so making your sentences to the point can save you from missteps.

Confusion will stem from complex and extended paragraphs. Make your questions clear and to the point. When asking a manufacturer a set of questions, I’ve learned to list them out in numerical order with one question on each line like the following:

Where is your factory located?

Have you produced for a American company before?

Can I come visit your factory?

Though these are basic questions, you’re more likely to get a better response by writing your message in an organized way.

Once you feel you’ve built a strong connection with the sales rep, it’s time to make connections to other people at the factory. We usually recommend that you know at least 2 people at a factory you work with, in case something happens to the first. That way if your sales rep doesn’t respond, you have someone else to get in touch with. A sales rep may not respond for a number of reasons such as going on vacation, getting laid off, or just simply getting lost in communication – the same way any company employee across the globe might not respond for a bit.

If you want to be introduced to another employee that works at the manufacturing company, simply ask to be introduced to a manager or another sales rep. Your main reason for wanting another introduction can be to confirm information or to have a employee to fall back on. Your sales rep should understand this and be willing to introduce you to other employees at their company.

The best way to have a great manufacturing experience is through constant communication.

If I am looking at a new supplier or distributor in a production run, we often touch base with the manufacturer about 3-4 imes a week.

This will keep your production run top of mind for your manufacturer.

Final word

Manufacturing is always going to be a continuous process and when business in China relies heavily on relationships, maintaining the connection to your manufacturer will be crucial over time.

When you’re saving a lot on production costs by producing overseas, those language and time zone barriers will be well worth it. Finding a manufacturer who is capable and trustworthy will be hard, but once you’ve found one it should be full steam ahead towards finishing a production run.

The initiative of a company to engage with a manufacturer is what sets a successful production run apart. It’s about time you take control of your supply chain and start producing your products in a effective manner!

Learn more about supply chains, shipping, and fulfillment:

Nathan Resnick is a serial entrepreneur who is the CEO of Sourcify, a platform that makes manufacturing easy. He has brought dozens of products to life over the course of his career and used to live in China.